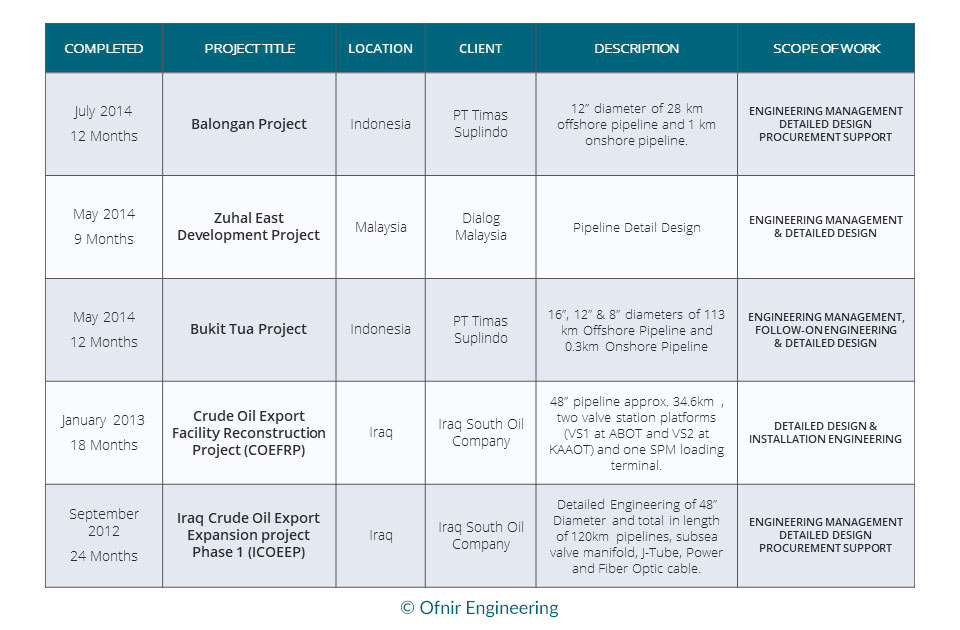

Experience

Metrod, KlangMALAYSIA

Copper Hot Rolling Mill Design and Fabrication

- COMPLETED –

MARCH 2016

- DURATION –

6 MONTHS

- CLIENT –

METROD

SCOPE OF WORK

- Detailed measurement and replication of Copper Rolling Mill machine

- 3D assembly drawings

- 300 complete fabrication drawings of individual parts

Component Detailed Drawings // Full 3d Assembly // Fabrication Drawings // Fabrication Support

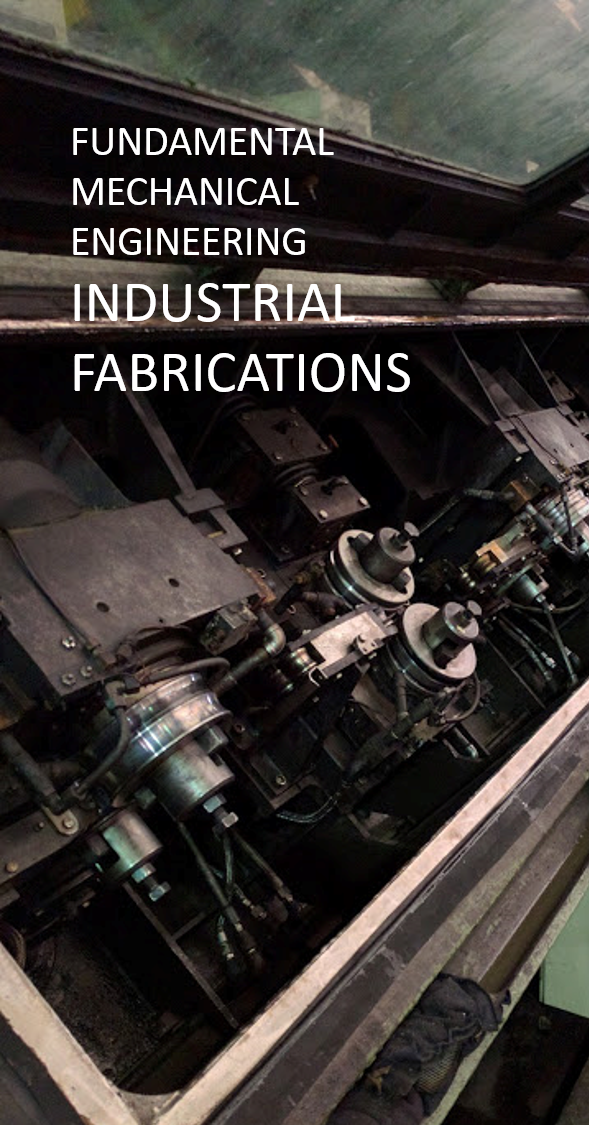

SabahMALAYSIA

FLNG Project

- COMPLETED –

DECEMBER 2015

- DURATION –

7 MONTHS

- CLIENT –

KROHNE OIL AND GAS

SCOPE OF WORK

- Detailed design of 5 non standard skids for FLNG platforms

- 3D assembly drawings

- In depth design optimisations within safety limits

Detailed Engineering Design // STAAD.Pro Software Design and Analysis // Intergraph Caesar II Stress Analysis // Fabrication Drawings // Fabrication Support // Fabrication Inspection and Integrity Assessment

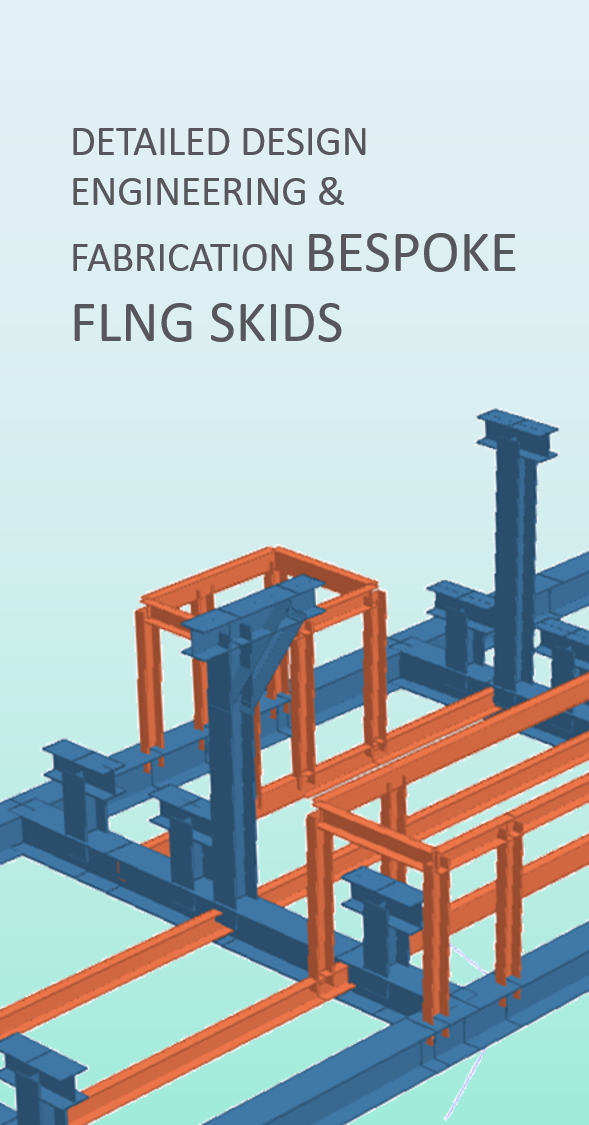

FSO Gagak Rimang, Banyu UripINDONESIA

Banyu Urip Export Facilities Project

- COMPLETED –

JANUARY 2015

- DURATION –

38 MONTHS

- CLIENT –

PT REKAYASA ENGINEERING EXXON MOBIL

SCOPE OF WORK

- Mooring tower at 33 water depth

- 20 inch / 23 km offshore pipeline

- Detailed designed & installation Engineering of the 20” offshore pipeline

Project Management // Detailed Design & Installation Engineering of the 20” Offshore Pipeline // ABAQUS Finite Element Analysis (FEA) for pipeline crossings // ABAQUS Finite Element Analysis (FEA) for HT (High Temperature) pipeline lateral buckling // ABAQUS Finite Element Analysis (FEA) for ET Subsea Riser & Tie-In Spool Analysis considering Platform Movement due-to Seismic Activity // Pipeline Process Engineering & Surge Analysis from Storage Tank Farm (EPC 1) to the FSO (EPC 4) Inlet using program OLGA & PVT Simulator // Structural Engineering Support Service for Mooring Tower Engineering & Fabrication // Procurement Support // Engineering Fabrication // QA QC for the EPC3 & Contract Management

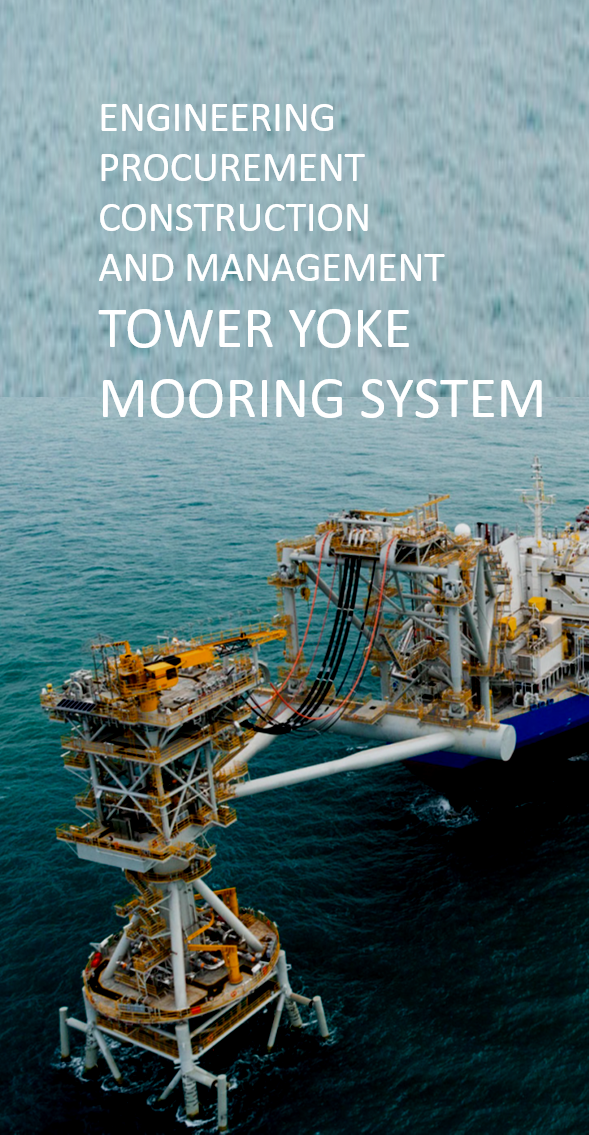

COLOMBO PORTSRI LANKA

Colombo Port Offloading Facilities

Integrity Assessment Project

- COMPLETED –

DECEMBER 2014

- DURATION –

7 MONTHS

- CLIENT –

CHEVRON

SCOPE OF WORK

- Cathodic protection assessment and installation

- 10 inch / 640 meter pipeline

- 15 years design life

Inspection And Verification Of Pipeline Wall Thickness // Procurement // Supply Installation Supervision // Testing And Commissioning Of The Cathodic Protection Sacrificial Anode

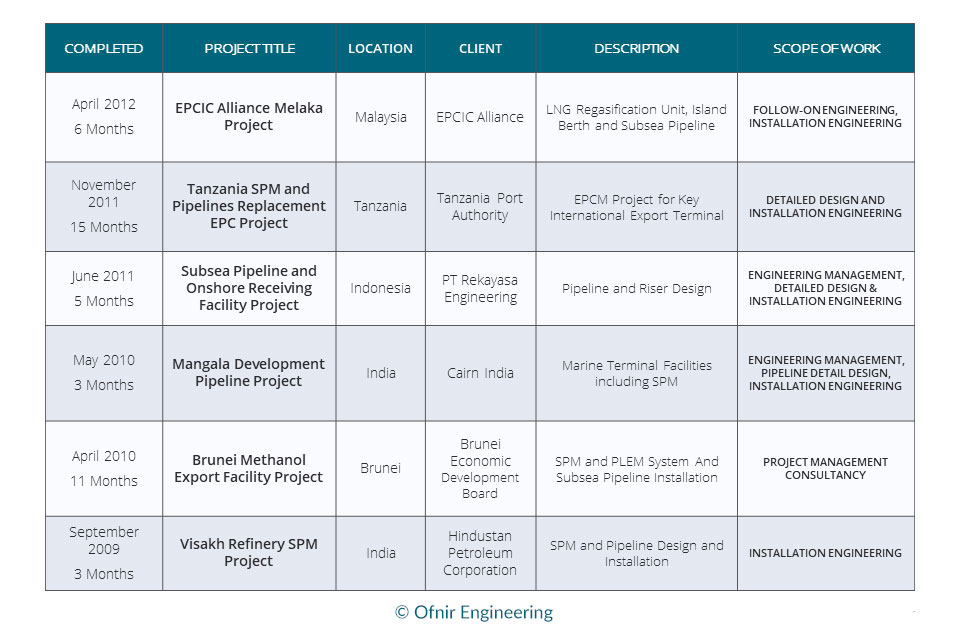

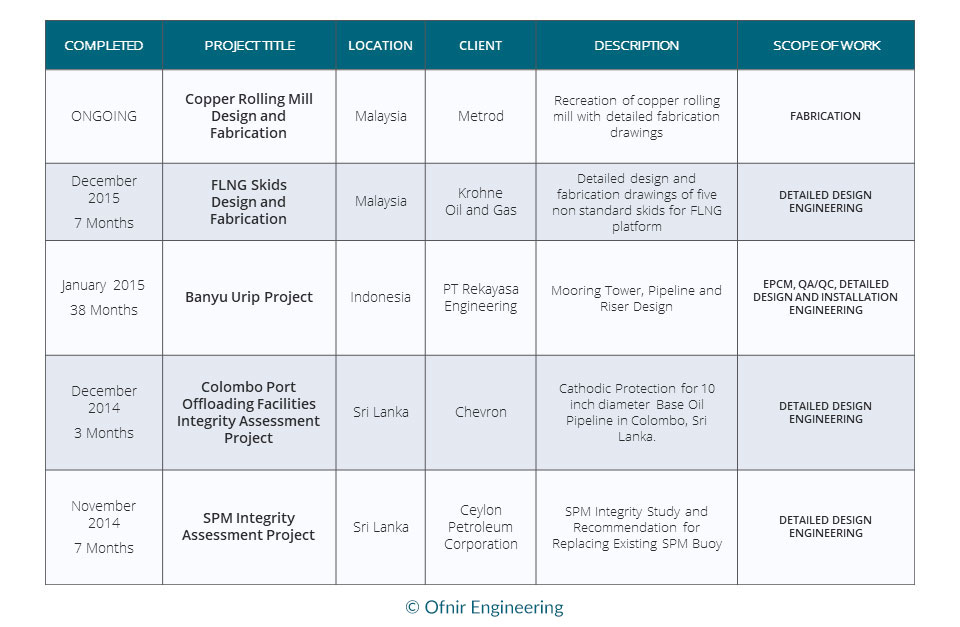

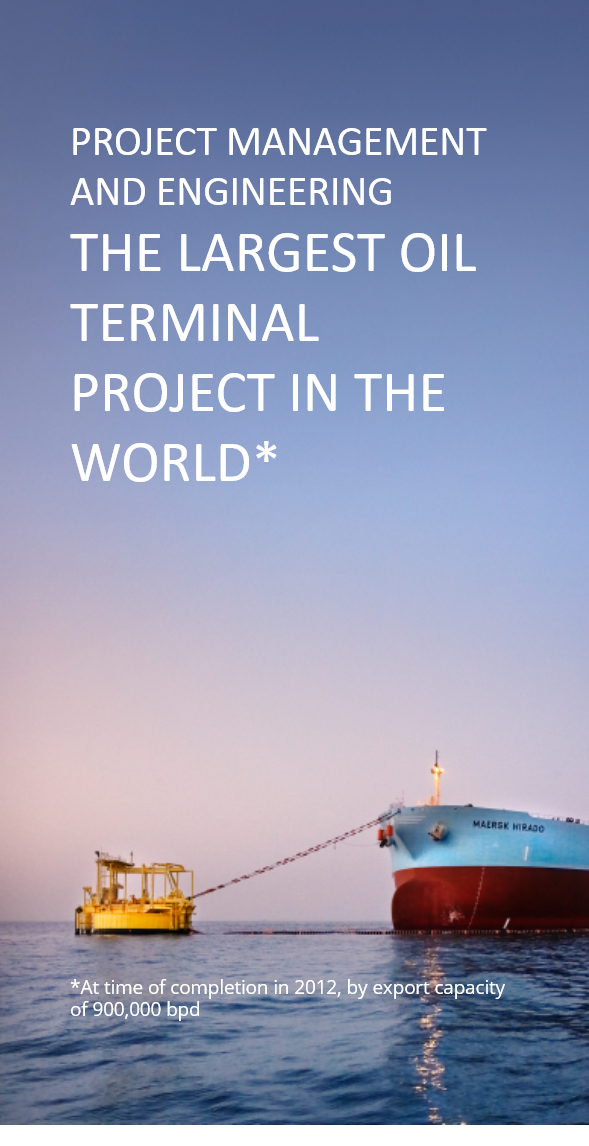

Al Basrah & Khor Al Amaya Oil Terminals IRAQ

Iraq Crude Oil Export Expansion Project (ICOEEP) Phase 1

- COMPLETED –

SEPTEMBER 2012

- DURATION –

24 MONTHS

- CLIENT –

IRAQ SOUTH OIL COMPANY

SCOPE OF WORK

- Two 48 Inch Pipelines

- A Third Pipeline Shore Approach Section

- Spur Pipeline

- Three SPMs

Engineering Management // Detailed Engineering Design of the Pipelines and Subsea Structures // Shore Approach Design // Trenching / Backfilling Design // Tie-in / Expansion Spool Design // Hanger / Tie-in Flange Design // Dropped Object Study // Subsea Valve Manifold Structural Design // Material Take-Off // Pipeline Operation and Maintenance Philosophy // Specifications // Drawings // J-Tube Design // Procurement Support Services (Technical Support) // Pipeline / Subsea Structure // Final Design Report // Pipeline/SPM/PLEM/SSVM Installation Engineering

Dar Es SalaamTANZANIA

Tanzania SPM Replacement Project

- COMPLETED –

MARCH 2012

- DURATION –

20 MONTHS

- CLIENT –

TANZANIA PORTS AUTHORITY

SCOPE OF WORK

Ofnir designed and developed an offshore terminal for the import of crude oil and white products capable of mooring tankers in the range of 40KDWT to 150 KDWT including;

- 28 inch / 4.5 km crude pipeline

- 24 inch / 4 km white product pipeline

Engineering Management // Design Basis Memorandum // Pipeline Detail Design // Shore Approach Design and Determined Burial Depth Requirement at the Surf Zone // (MTO) Material Take-Off // Cathodic Protection System Design for Pipeline // Interface with Certifying Authorities // Mechanical Protection / Trenching // Estimated Pipeline Thermal Expansion and Requirements for Expansion Absorbing Devices or Thrust Blocks // Expansion Offset Sizing // Final PLEM Arrangement // Final Design Report

Ofnir Engineering

Work Experience

Ofnir Project Listing